MITCHELL 308 had been loaded the face-gears since 80's.

Although they are silent at the beginning of use , they become rough after a few days use.

I consider about this.

The numbers of teeth are 49 and 10.

It means that a tooth meets all of the teeth.

MITCHELL 308 had been loaded the bevel-gears until 70's.

They need much costs and much precision. So , this system cannot be used.

When you think the bevel-gears as a pair of the friction wheels , it can be shown as this picture.

They are the cone shapes. So , they don't slip.

Try to think same.

The wheels slip on their surfaces , because the pinion is cylindrical.

When the no-slipping point is the blue circle , the main gear is faster at the outside and the pinion is faster at the inside.

The teeth of the main gear looks like the diamond of cards. So, it is called "diamond-cut".

The circle , made by the diagonal line of the diamonds , is the blue circle of above picture.

The teeth is tapered at the both of the inside and the outside of the circle.

Then I calculate the diameter of the blue circle. It is called the pitch circle diameter (PCD).

The PCD is the diameter of the friction wheel of above pictures.

The PCD of the pinion is 10/49 of the PCD of the main gear.

I calculate the module of the pinion to calculate PCD of it.

The module shows the size of the teeth.

dk=(n+2)*m

(dk:the external diameter , n:the number of the teeth , m:module)

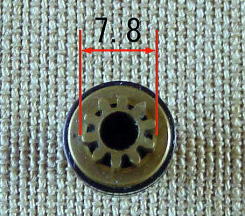

On this pinion...

7.8=(10+2)*m

m=7.8/12

=0.65

The module of this pinion is 0.65.

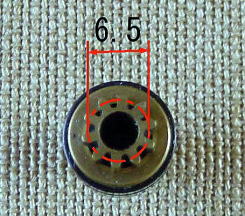

m=PCD/n

(m:module , PCD:pitch circle diameter , n:the number of the teeth)

On this pinion...

0.65=PCD/10

PCD=6.5

So , PCD of this pinion is 6.5mm.

PCD of the main gear is 49/10 of PCD of the pinion. (Or , m*n=0.65*49)

PCD=6.5*49/10

=31.85

PCD of the main gear is 31.85mm

On the main gear of the face-gears , the inside of PCD cannot use. If the inside touches the pinion , the rotation becomes heavier.

.

Really , the inside of PCD does not touch.

Therefore , the effective width of this gear is only (33.6-31.85)/2=0.875mm of the width of (33.6-29.1)/2=2.25mm.

So, these gears become rough soon.

If the PCD were smaller , the gears had more durability. This picture is the face-gears of ABUMATIC 170. The outside of PCD is wider.

But , MITCHELL 308 cannot be redesigned like this , because its body is too small. MITCHELL 308 had been designed for the bevel-gears of 4.4:1 ratio in 1960.